The rise in automation in our home lives and work lives has grown to new levels in recent years.

From smart home connectivity to lightning-fast apps that can order us a car, a meal, or anything else we might need with a few clicks and swipes, automation has changed the way we complete tasks, activate home controls, maintain product systems, and much more. We expect our connected household devices (kitchen appliances, TVs, HVAC systems, lighting, etc.) to work flawlessly via the Iinternet.

It’s a similar world for companies working in industrial solutions. Manufacturing facilities, high-tech buildings, production factories, supply chain warehouses, and other major work arenas expect their industrial machinery and automated systems to perform just as well.

More manufacturers and building owners are investing in technologies like Industrial IoT hardware platforms, cloud computing, edge computing, and industrial design systems. Using artificial intelligence (AI), robotics, edge devices, and cloud services, businesses are making a strong push toward digital transformation to optimize their data, equipment, workers, and profits.

What Is the Industrial Internet of Things (IoT)?

In a nutshell, the Industrial Internet of Things (IIoT) is the application of Internet of Things (IoT) technology in the industrial sector. It involves the use of connected machinery, sensors, devices, and other technology to collect and exchange data.

The collected data is then analyzed and applied to work systems to improve the efficiency, productivity, and safety of industrial processes. The number of industrial IoT platforms and applications continues to grow. As a result, there are many new companies looking to capitalize on IoT technology.

The Benefits of Applying Industrial IoT

Industrial IoT has expanded very quickly in recent years. Just two years ago, the Industrial IoT market was valued at approximately $216 billion, according to Statista. By 2027, the market value is expected to skyrocket past the $900 billion mark.

This fast growth means that industrial IoT processes are quickly gaining popularity with businesses by helping them operate more efficiently and reliably. Here's how businesses can benefit by using industrial IoT systems:

- Real-time data reporting: Using industrial IoT, businesses can monitor and track their operations in real-time. This data activity provides businesses with a more accurate understanding of their processes.

- Identify trouble spots: Careful analysis of data points can help business leaders find trouble spots in their operations and pinpoint the areas that need improvement. Fixing these targets can help businesses to reduce downtime and optimize operations.

- Make more intelligent decisions: Using industrial IoT sensor technology in plant operations can offer insights into equipment automation, repair or maintenance issues, and other manufacturing targets. This can forewarn management of upcoming challenges and help them preemptively and intelligently address issues.

- Create better work conditions and plant safety for employees: Because industrial IoT systems can help businesses monitor and control their operations in real time, they are able to identify potential safety hazards and prevent them before they occur. This reduces the risk of accidents and improves overall workplace safety.

- Improve customer experience and satisfaction: By optimizing operations with IoT, businesses can respond more quickly to customer requests about products and services, while delivering a better overall customer experience.

More specifically, increasing automation can give businesses streamlined predictive maintenance, actionable insights, and improved operations:

Streamline Predictive Maintenance

One of the key facets behind Industrial IoT is predictive maintenance, which allows industrial companies to anticipate issues or breakdowns with their equipment before they actually occur. It’s a look into the future, based on data, that gives companies an edge.

In industrial operations, there are high amounts of energy consumption across the control systems, which can lead, if left unchecked, to machinery breakdown. However, when asset tracking and smart devices are used together with an IoT control center to perform predictive maintenance, businesses can more accurately predict when equipment is likely to fail.

This predictive maintenance helps businesses avoid unplanned downtime and reduces the need for emergency repairs, thus saving the business large amounts of money in repairs.

Companies that use Asset Condition Monitoring (ACM) are able to track their assets' data in real time. Activated sensors create a targeted analysis that can then generate predictive maintenance plans for all the business assets under smart controls.

Create Actionable Insights From Connected Sensors

How is industrial IoT connected to the internet? Businesses can gain actionable insights from connected sensors in an industrial IoT platform. Internet gateways can be used to collect and send data from industrial IoT devices to the cloud, or to control industrial IoT devices remotely.

When industrial IoT devices work through a central control system, they can communicate with each other through this network, which is often called a “fog network.” Fog networks put storage and processing components at the edge of the cloud, where data sources, such as application users and sensors, exist. This decentralized infrastructure collects and sends data from industrial IoT devices to the cloud or to other connected IoT devices.

These systems involve a whole range of computation, monitoring, sensing, automation, communication, and decision-making.

Improve Industrial Operations

Industrial IoT operations benefit businesses by enabling them to collect and analyze real-time data from their equipment and processes.

For example, sensors and other industrial IoT devices monitor the performance of machinery and equipment. The collected data from these devices can be used to identify production trends and patterns. After careful data analysis, management can use the data to help improve device allocation efficiency and productivity.

Additionally, the industrial IoT can enable businesses to monitor and control their equipment remotely, allowing them to respond quickly to changes in their operations and reduce downtime. Having this data coming in from all the connected sensors gives business managers a higher level of knowledge to evolve their decision-making.

How To Adopt Industrial IoT Technology

Businesses need to understand how to most effectively use industrial control systems. Business models are different in every industry, so the process of adopting this technology is to use interconnected systems run through IoT platforms.

Industrial control systems (ICS) can be used to manage and monitor processes in machinery and equipment. These systems typically consist of sensors and other devices that collect data from the machinery and equipment, as well as control systems that use this data to adjust the operation of the equipment in real time. This allows companies to optimize the performance of their machinery and equipment, ensuring that it is operating efficiently and safely. Additionally, ICS can be used to monitor the health of the equipment and alert operators when maintenance is needed.

These systems can also handle the environmental characteristics of buildings. This includes the technology controls that are typically used in office buildings to manage heating, ventilation, and air conditioning (HVAC) systems.

For example, sensors can be used to monitor the temperature and humidity levels in different parts of the building, and the control system can adjust the operation of the HVAC system to maintain comfortable conditions for occupants.

Industrial control systems can also manage the lighting and security in a facility, and automatically adjust these systems as needed. For example, the lighting system can be set to turn off lights in unoccupied areas, and the security system can be used to monitor access to the building and alert security personnel of any potential issues.

These systems are beneficial, but, like all technological advances, IoT systems are not risk-free.

The risks associated with industrial IoT are mainly cyber-attacks. In a network hack, cyber thieves could access sensitive data or even take control of devices. If devices are not properly secured and monitored, these devices could be used to launch attacks against other systems.

Additionally, if devices are not properly configured, they could overload the network or cause other systems to fail. Other risks include data breaches, system failures, and privacy concerns.

Upgrade Your Operational Technology Using Industrial IoT

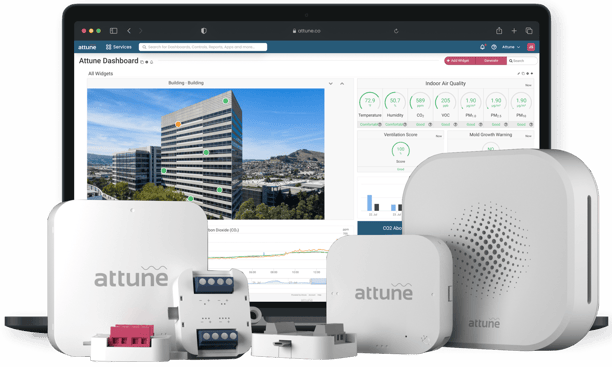

Attune can help. If you’re a commercial real estate building owner/operator, a facilities manager, a building engineer, or an energy manager, you need to be in tune with Attune.

We can help your buildings run smarter, with our custom IIoT solution. Our platform is designed to bring greater transparency to your data and higher visibility to any challenges up ahead.

We have taken the knowledge gained in our earlier era as Senseware and used it to create Attune sensors and monitoring systems that bring greater levels of awareness to your facility. Start your digital transformation today.